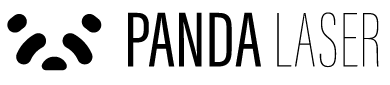

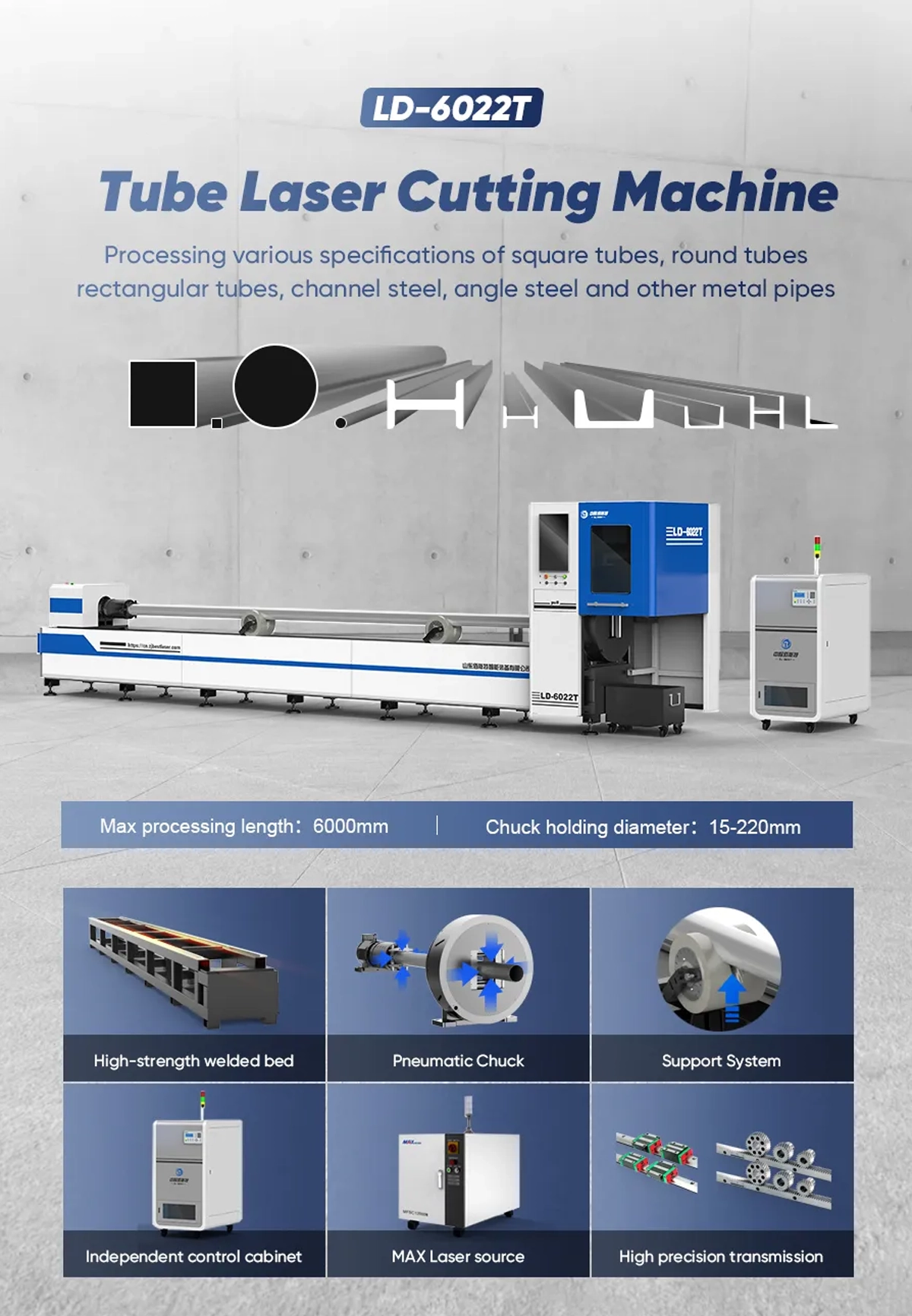

| LD6022T Tube Laser Cutting Machine | ||

| Model | LD6012T | LD6022T |

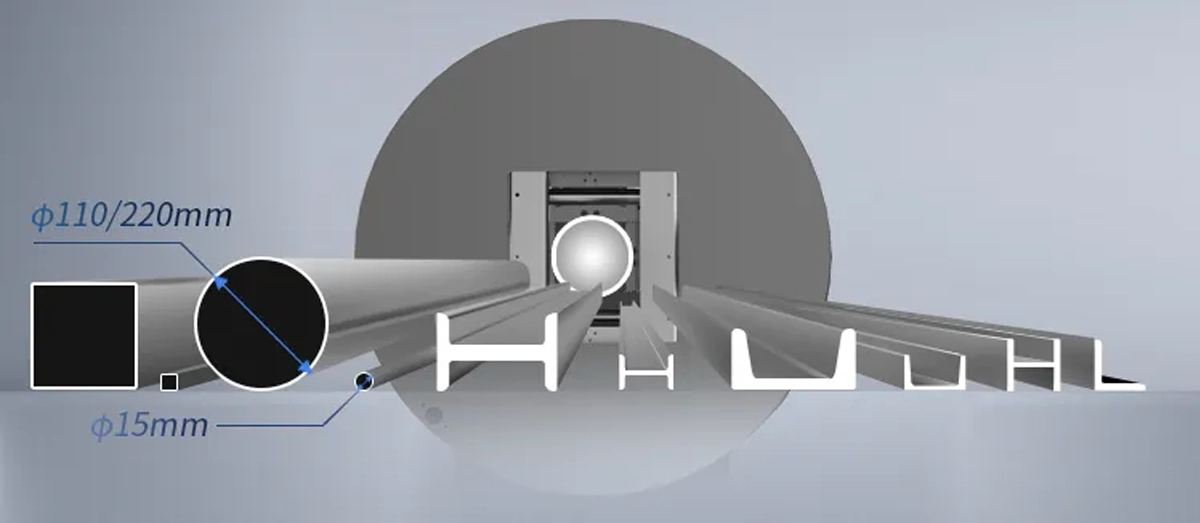

| Chuck holding diameter | 15-120mm | 15-220mm |

| Max processing length | 6000mm | |

| Positioning accuracy | ±0.03mm/m | |

| Repeated positioning accuracy | ±0.02mm/m | |

| Max acceleration | 1.0G | |

| Max positioning speed | 80m/min | |

| Laser power | 1KW-3KW | |

| Other dimensions can be customized | ||

LD6022T Tube Laser Cutting Machine.

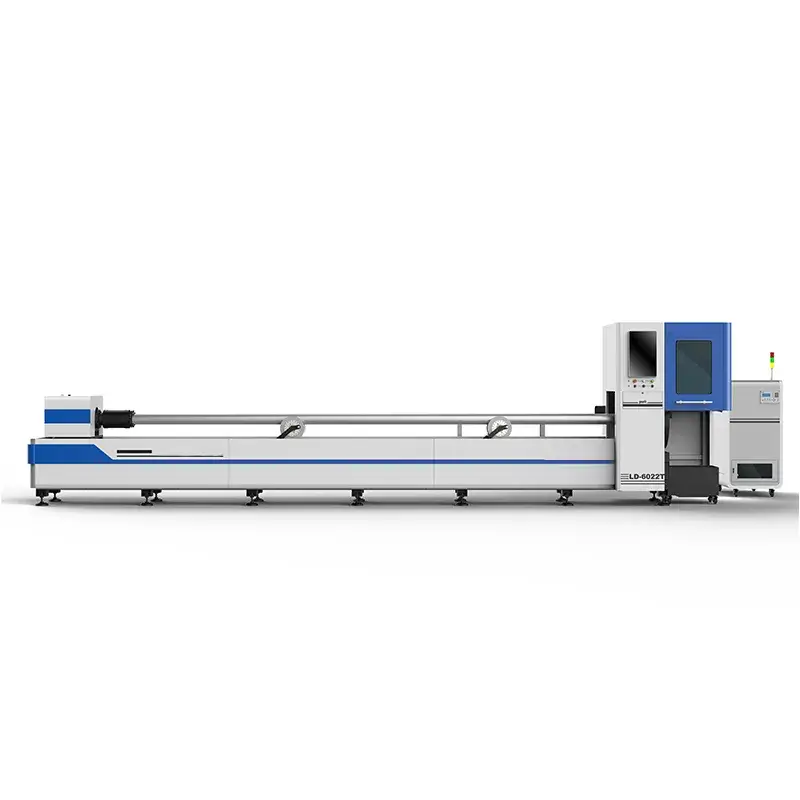

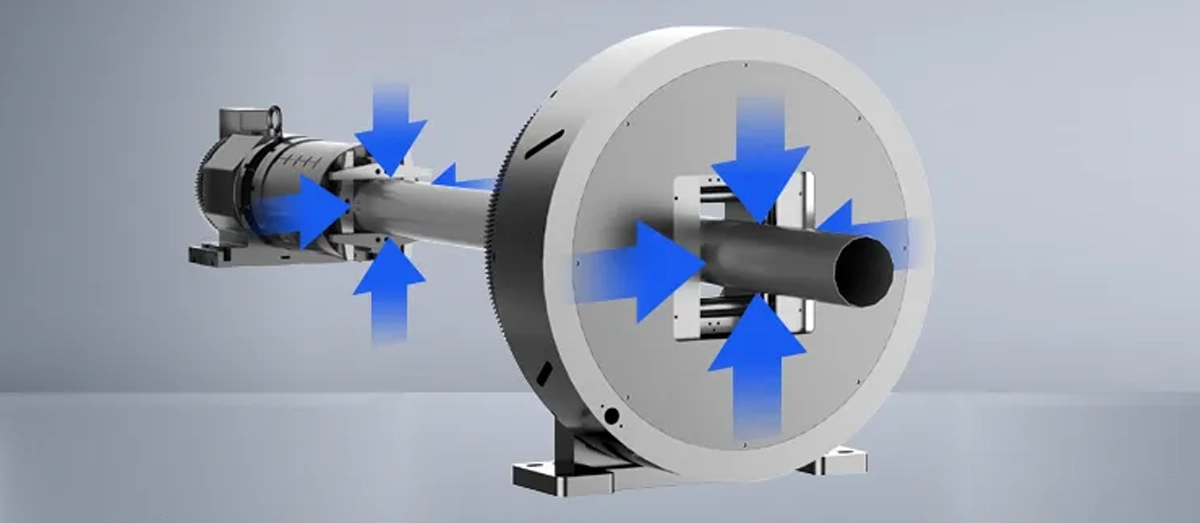

The transmission system adopts internationally renowned brands, with stable transmission, fast speed and high positioning accuracy. It has stable operation, low noise, shock absorption and buffering, compact center distance and small shape, constant transmission ratio, wide selection of peripheral speed and power, accurate transmission, high efficiency, compact structure, reliable operation and long life. The instantaneous transmission ratio is constant, and the transmission ratio range is large, which can be used for deceleration or acceleration. The range of speed (circumferential speed of the knuckle circle) and transmission power is large, which can be used for high-speed, medium-speed and low-speed transmission; the power applicability range is wide, the transmission efficiency is high, and it is suitable for short-distance transmission.

The integrated power distribution cabinet design has the following advantages:

- The failure rate is low. Since the failure rate of integrated circuits is relatively low compared to discrete component circuits, the failure rate of the whole machine circuit is reduced.

- The circuit is simple. Due to the use of integrated circuits, the design, debugging and installation of the whole machine circuit are simplified, especially after some special integrated circuits are used, the whole machine circuit is simpler.

- The energy consumption is small, and the integrated circuit also has the advantages of small power consumption, small size and economy.

- High cost performance. Compared with discrete component circuits, the performance indicators of the whole circuit composed of integrated circuits are higher. Compared with discrete electronic component circuits, the cost and price of integrated circuits are lower.

- Strong reliability, the integrated circuit has the advantages of high reliability, thereby improving the reliability of the circuit operation of the whole machine, and improving the working performance and consistency of the circuit.

|

|

|

HIWIN guide YYC gear rack |

YASKAWA motor |

|

|

|

Shimpo reducer |

MAX laser resource |

|

|

| Auto focus laser head | The fourth generation steel mold high pressure cast aluminum beam |

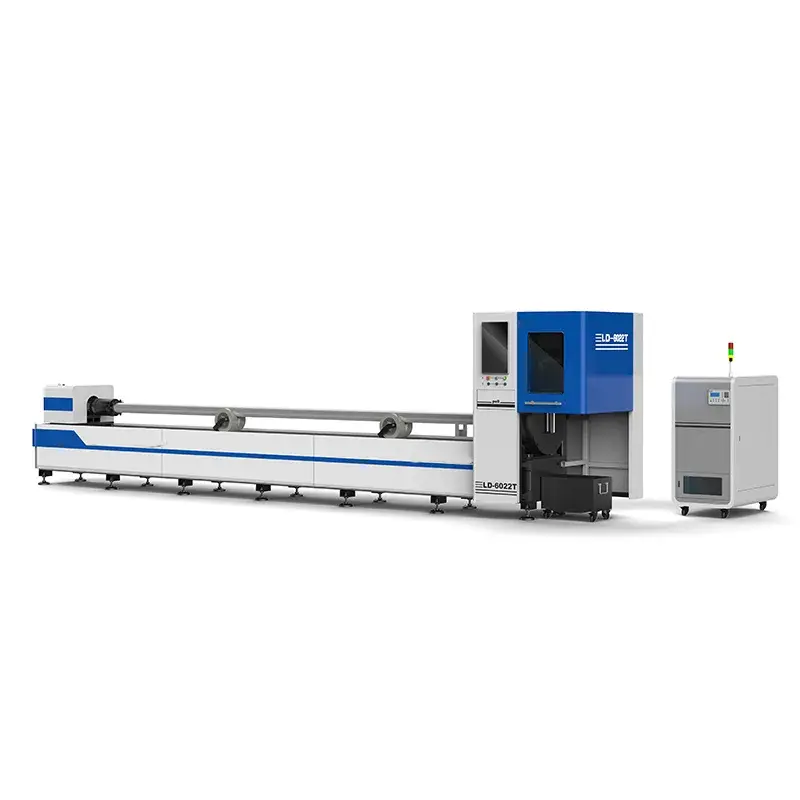

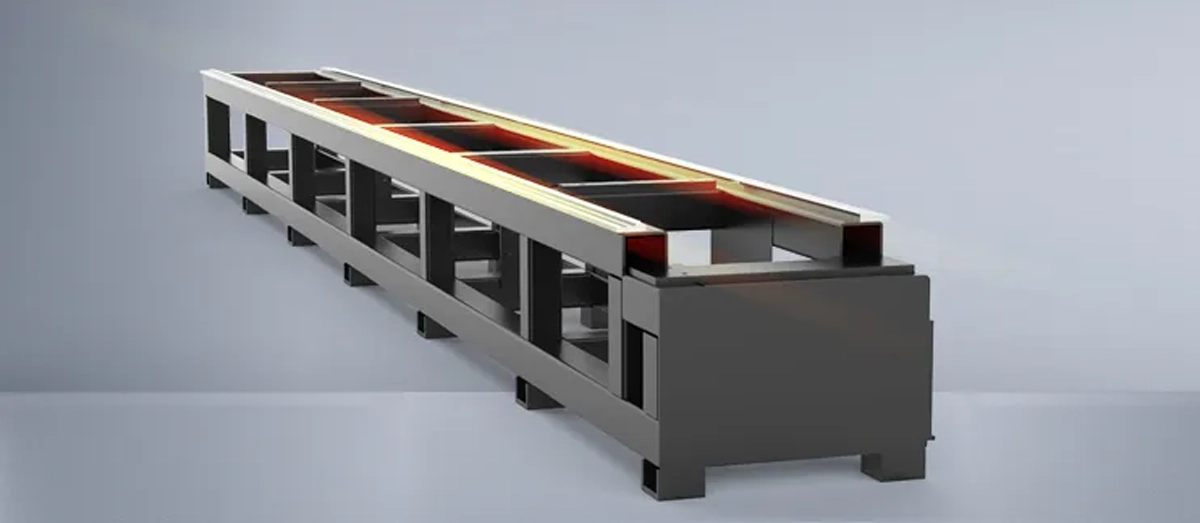

The whole equipment bed adopts split bed design, improve the overall stiffness, enhance the local strength and strengthen the contact stiffness

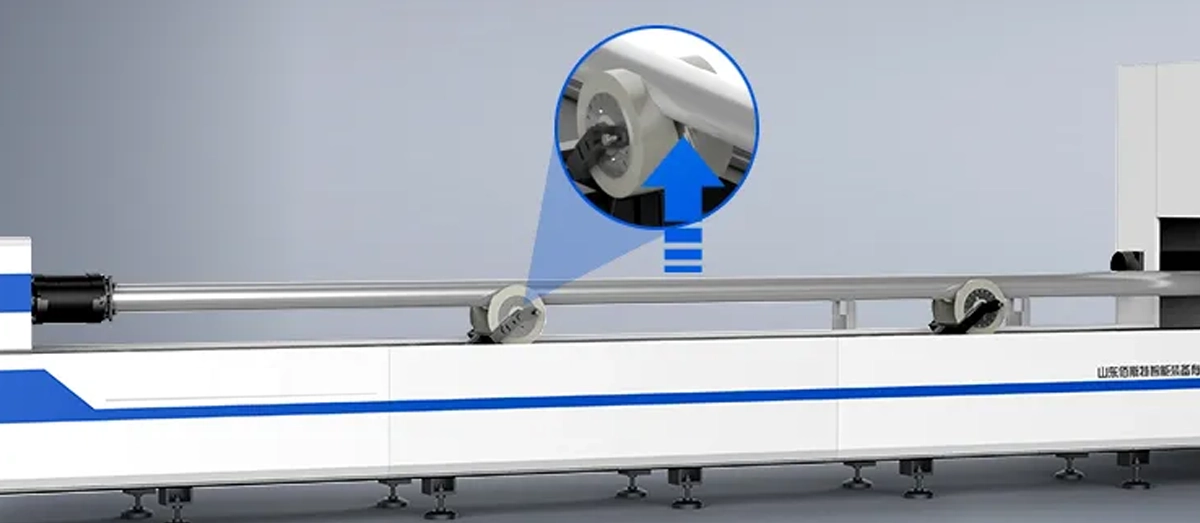

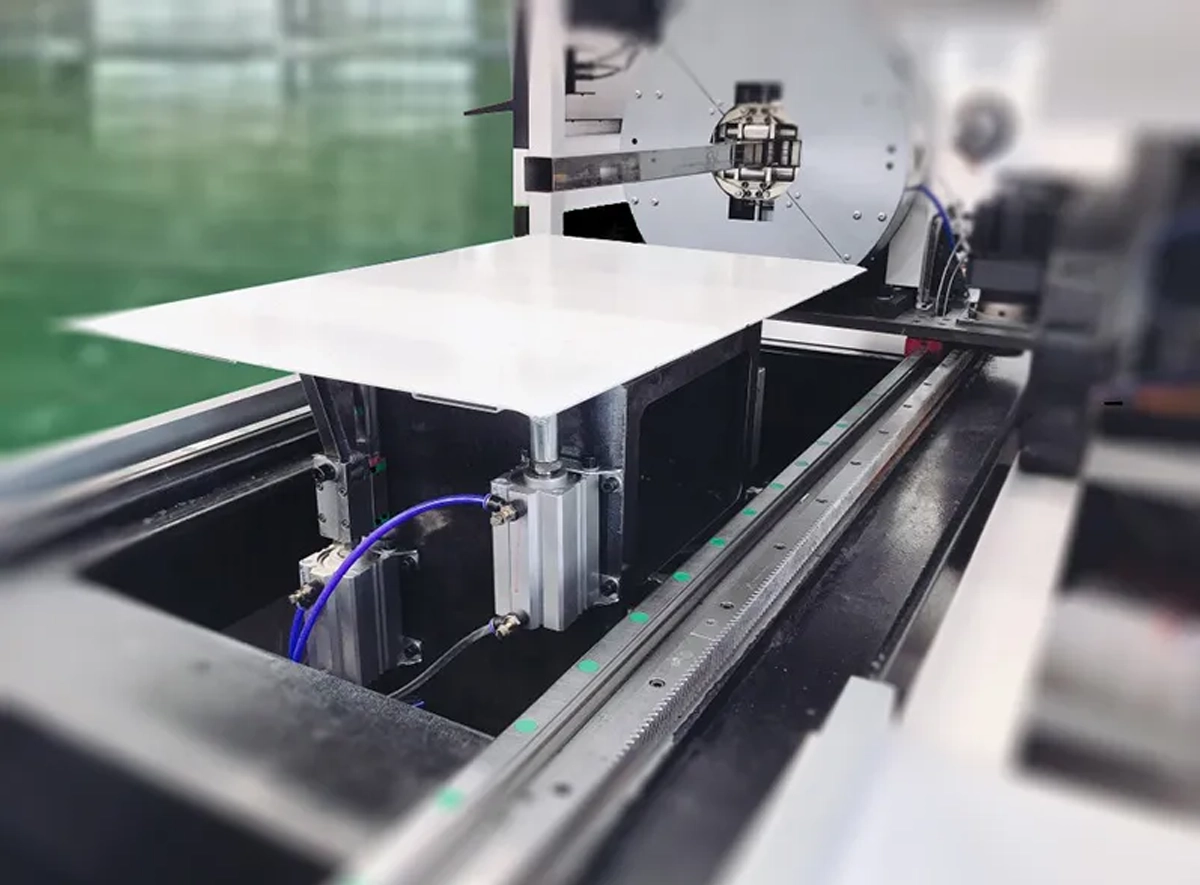

The anti-shake and stable support can prevent the large deflection of the pipe and improve the cutting precision.

The bed structure is optimized and upgraded, after high-temperature annealing heat treatment, vibration aging and other precision processing, the welding stress and processing stress are effectively eliminated, the product accuracy is guaranteed, and the bed is more reliable

Front and rear double pneumatic chucks, full stroke self-centering, high positioning accuracy, one-button clamping, adjustable clamping force, stable and efficient.

Chuck clamping diameter: 15-110/220mm, supports high-speed and high-quality cutting of stainless steel pipes such as square pipes, round pipes, I-beams, channel steels, angle steels, and carbon steel pipes.

| Precautions for laser cutting machine maintenance | ||

| Maintenance period | Maintenance contents | Maintenance contents |

| Every day | 1. Check whether the temperature setting of the chiller is normal (the set temperature is 20 ± 1 ℃) ; | Ensure that the temperature of the cooling water supplied to the laser is normal |

| 2. Check whether the water seal, water temperature and water pressure of the chiller meet the requirements; | Ensure the normal operation of the equipment and prevent water leakage | |

| 3. Ensure that the working environment of the chiller is dry, clean and ventilated; | It is conducive to the good operation of the chiller | |

| Monthly | 1. Use neutral detergent or high-quality soap to remove the dirt on the surface of the chiller. Do not use benzene, acid, grinding powder, steel brush, hot water, etc; | Ensure that the surface of the chiller is clean |

| 2. Check whether the condenser is blocked by dirt. Please remove it with compressed air or brush to ensure that the surface of the chiller is clean; | Ensure the normal operation of the condenser | |

| 3. Clean the air filter screen:

a. Open the panel of the assembled air filter, pull up the air filter screen of the unit and draw it out; b. The dust on the filter screen can be removed by vacuum cleaner, air spray gun and brush. After cleaning, if the filter screen is wet, shake it to dry and then replace it. c. Cleaning cycle: once every two weeks. If the dirt is serious, please clean it irregularly. |

Prevent poor cooling caused by poor heat dissipation and burning out the water pump and compressor | |

| 4. Check the water quality of the water tank and follow up; | Good water quality can ensure the normal operation of the laser | |

| 5. Check whether there is water leakage in the water cooler pipeline ; | Ensure that there is no water leakage in the chiller | |

| Quarterly | 1. Check the electrical components (such as switches, terminals, etc.) and wipe them clean with a dry cloth; | Ensure that the surface of the electrical parts of the chiller is clean and prolong the service life |

| 2. Replace the circulating water (distilled water) and clean the water tank and metal filter screen;

If equipped with ROFIN laser resources, the cooling water can be replaced once every six months after adding an anti-corrosion inhibitor. If equipped with PRC laser resources, the cooling water can be replaced once every six months after adding propylene glycol; |

Ensure that the laser operates normally | |

| Attention:

a. Place the chiller and water pipe away from dust. b. Pull the power cord away from the socket and wipe the power cord clean; c. Cleaning the unit body. when cleaning the inside of the unit, do not let water splash on electronic parts; d. Completely drain the water from the laser resource, cutting head and water cooler. |

||

Common problems and solutions of laser cutting machine