The GS12525 Sheet Metal Fiber Laser Cutting Machine: Revolutionizing Metal Fabrication.

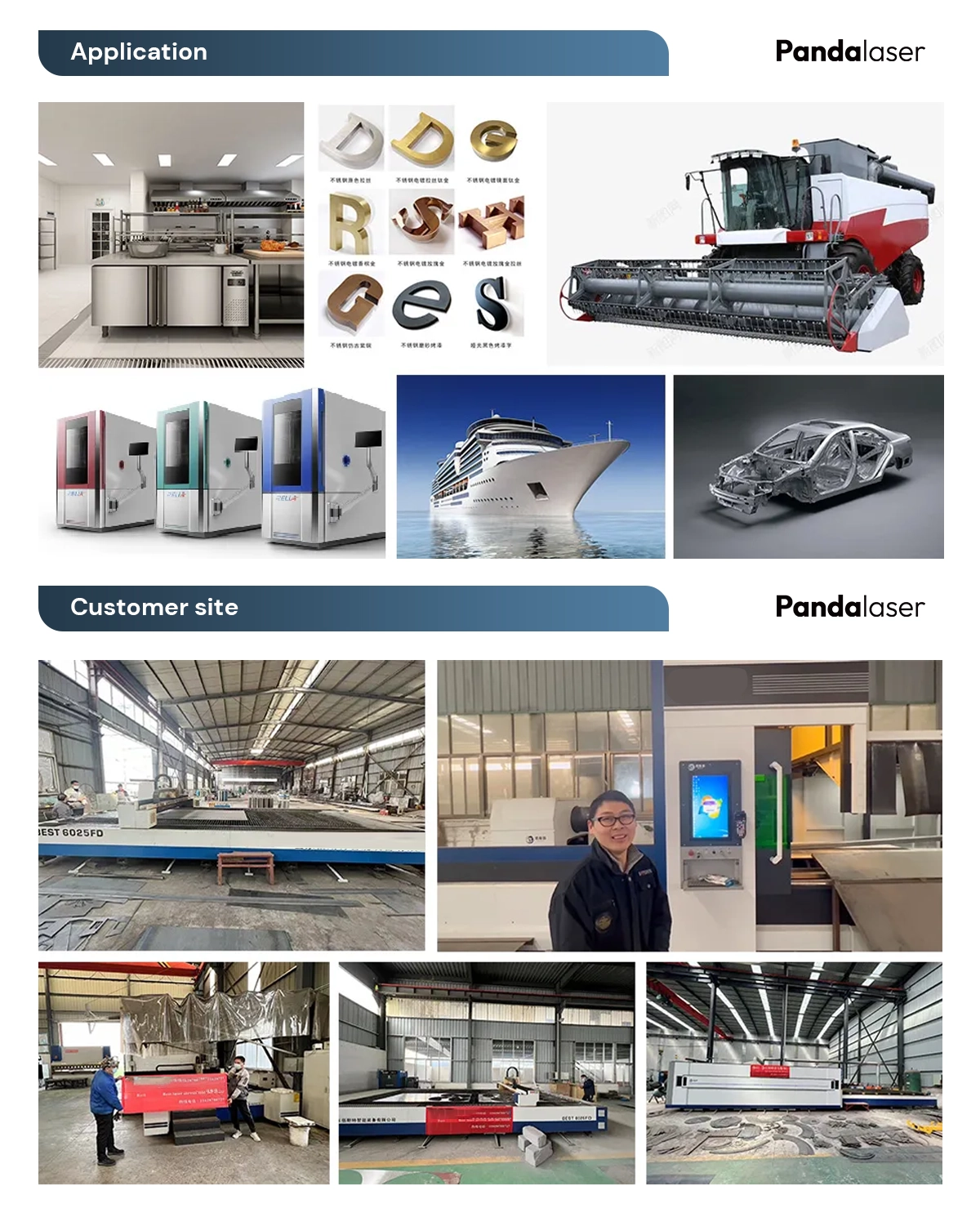

- Upgraded welded machine bed: Strong and stable for high-power equipment.

- Intelligent dust removal: Real-time, effective, and better dust removal.

- Environmentally friendly closed-loop design: No spillover, smoke, or dust pollution.

- Reliable transmission system: Stable, fast, low noise, compact, and efficient.

- Real-time monitoring: Enhance safety and observe cutting status.

- Improved cutting efficiency: Obstacle avoidance and automatic edge patrol.

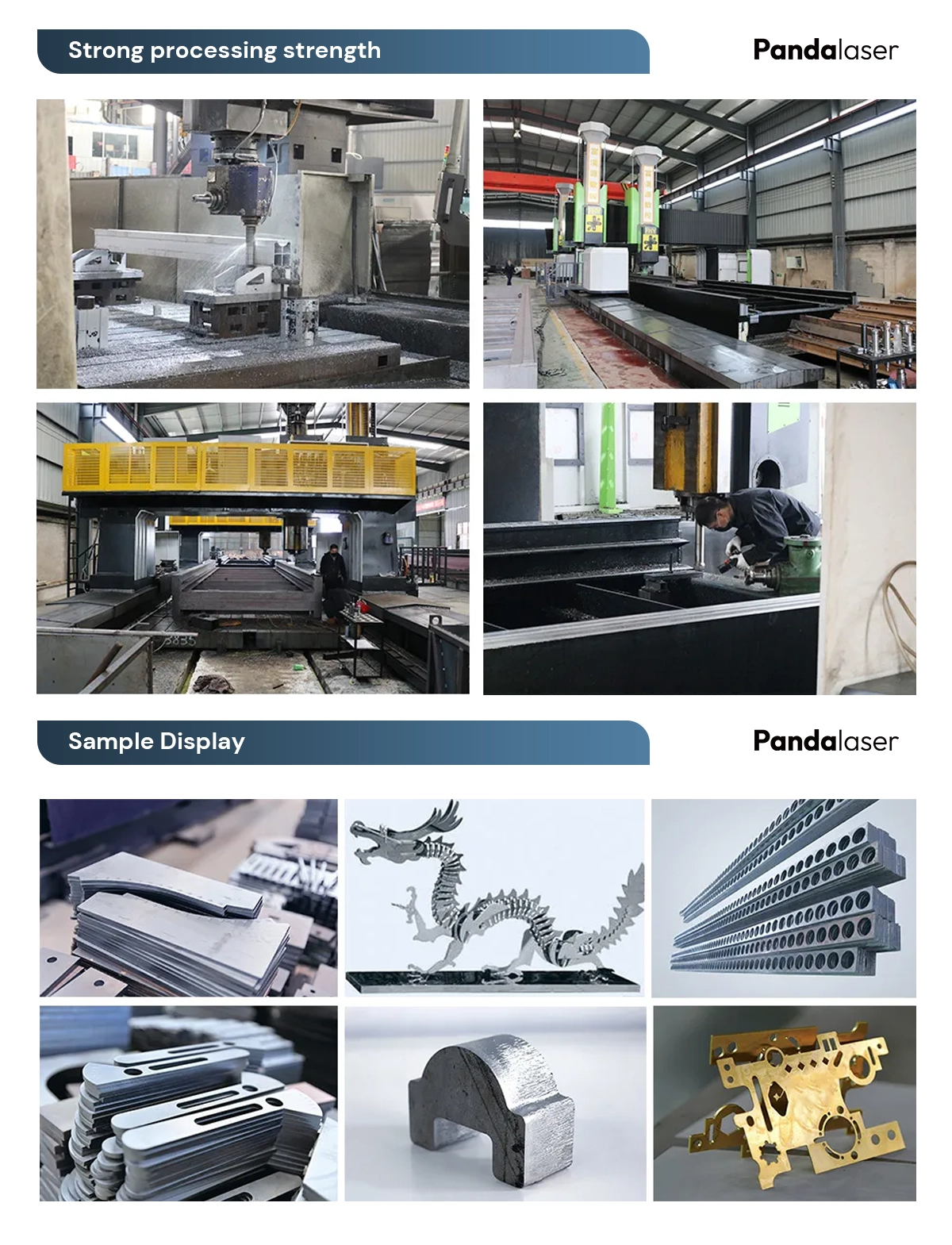

- Diversified plate processing solutions: High-quality and practical fiber laser cutting machines.

- Automatic focusing laser head: Convenient, accurate, and water-cooled.

- Steel mold cast aluminum beam: High precision, speed, and efficiency.

- Optimal choice for large-scale machines: Aluminum beam ensures longevity and accuracy.

|

|

|

HIWIN guide YYC gear rack |

YASKAWA motor |

|

|

|

Shimpo reducer |

MAX laser resource |

|

|

| Auto focus laser head | The fourth generation steel mold high pressure cast aluminum beam |

Plate welding bed design: higher strength of the bed, seamless connection between the two platforms, no deformation, and higher cutting accuracy

| Precautions for laser cutting machine maintenance | ||

| Maintenance period | Maintenance contents | Maintenance contents |

| Every day | 1. Check whether the temperature setting of the chiller is normal (the set temperature is 20 ± 1 ℃) ; | Ensure that the temperature of the cooling water supplied to the laser is normal |

| 2. Check whether the water seal, water temperature and water pressure of the chiller meet the requirements; | Ensure the normal operation of the equipment and prevent water leakage | |

| 3. Ensure that the working environment of the chiller is dry, clean and ventilated; | It is conducive to the good operation of the chiller | |

| Monthly | 1. Use neutral detergent or high-quality soap to remove the dirt on the surface of the chiller. Do not use benzene, acid, grinding powder, steel brush, hot water, etc; | Ensure that the surface of the chiller is clean |

| 2. Check whether the condenser is blocked by dirt. Please remove it with compressed air or brush to ensure that the surface of the chiller is clean; | Ensure the normal operation of the condenser | |

| 3. Clean the air filter screen:

a. Open the panel of the assembled air filter, pull up the air filter screen of the unit and draw it out; b. The dust on the filter screen can be removed by vacuum cleaner, air spray gun and brush. After cleaning, if the filter screen is wet, shake it to dry and then replace it. c. Cleaning cycle: once every two weeks. If the dirt is serious, please clean it irregularly. |

Prevent poor cooling caused by poor heat dissipation and burning out the water pump and compressor | |

| 4. Check the water quality of the water tank and follow up; | Good water quality can ensure the normal operation of the laser | |

| 5. Check whether there is water leakage in the water cooler pipeline ; | Ensure that there is no water leakage in the chiller | |

| Quarterly | 1. Check the electrical components (such as switches, terminals, etc.) and wipe them clean with a dry cloth; | Ensure that the surface of the electrical parts of the chiller is clean and prolong the service life |

| 2. Replace the circulating water (distilled water) and clean the water tank and metal filter screen;

If equipped with ROFIN laser resources, the cooling water can be replaced once every six months after adding an anti-corrosion inhibitor. If equipped with PRC laser resources, the cooling water can be replaced once every six months after adding propylene glycol; |

Ensure that the laser operates normally | |

| Attention:

a. Place the chiller and water pipe away from dust. b. Pull the power cord away from the socket and wipe the power cord clean; c. Cleaning the unit body. when cleaning the inside of the unit, do not let water splash on electronic parts; d. Completely drain the water from the laser resource, cutting head and water cooler. |

||