| Welding type |

Laser welding |

Argon arc welding |

| Welding method |

Spot or continuous welding |

Spot welding |

| Possible materials |

Stainless steel, carbon steel, galvanized sheets, aluminum, etc. |

Stainless steel, carbon steel, galvanized sheets |

| Minimum thickness |

0.5-4mm |

1-12mm |

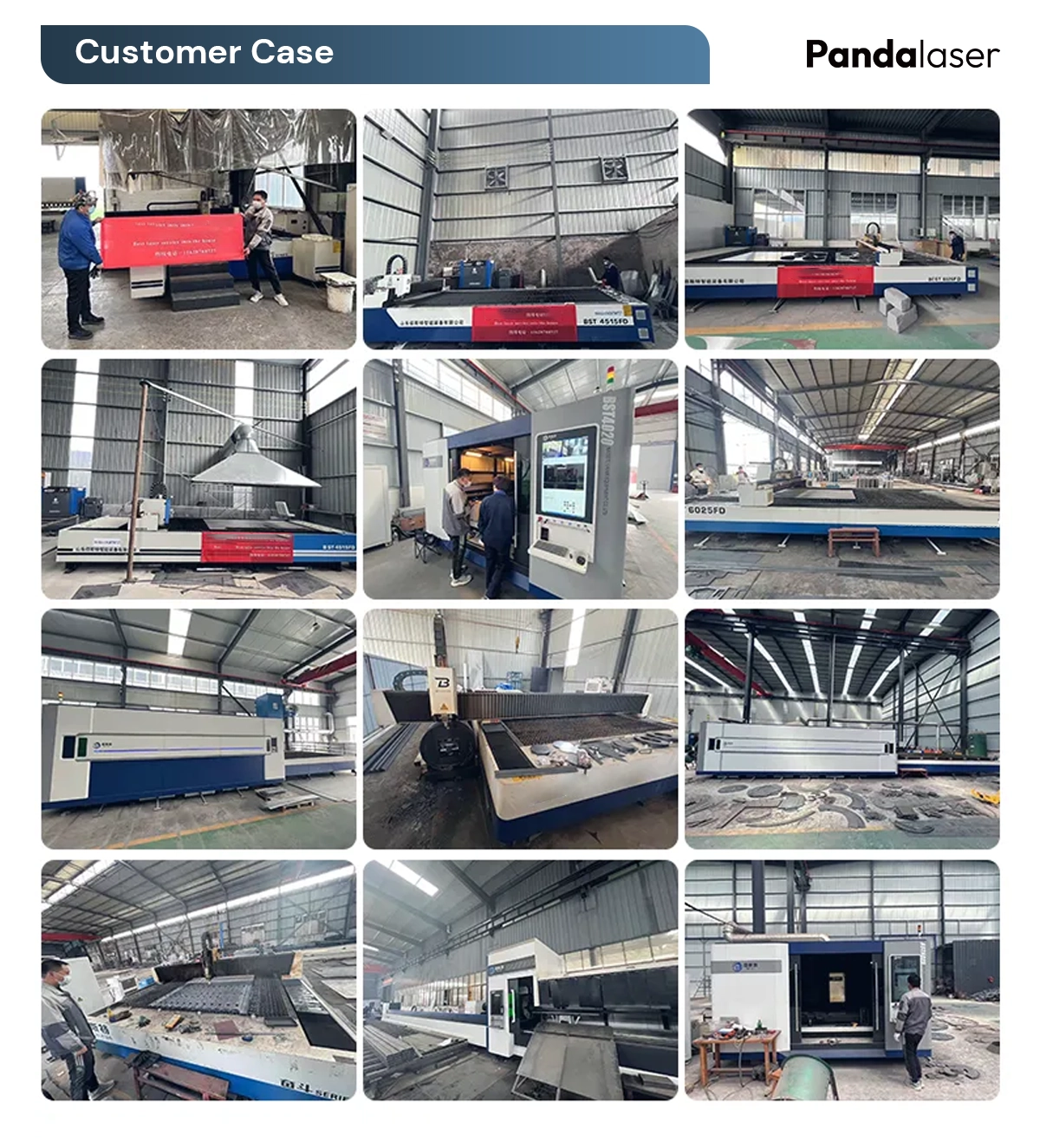

| Material deformation |

Small |

Large |

| Welding speed |

0-8m/min |

0-1m/min |

| Post-weld processing |

Minimum / none |

Required |

| Service level |

Easy |

Difficult |

| Safety and environmental protection |

Relatively safe and environmentally friendly |

Not |

| Cost of service |

General worker (can be hired after simple training) |

Professional welder |

| Consumable parts |

Lens, nozzles |

Electrodes, Porcelain nozzles |

| Gas |

Argon/Azot |

Argon |

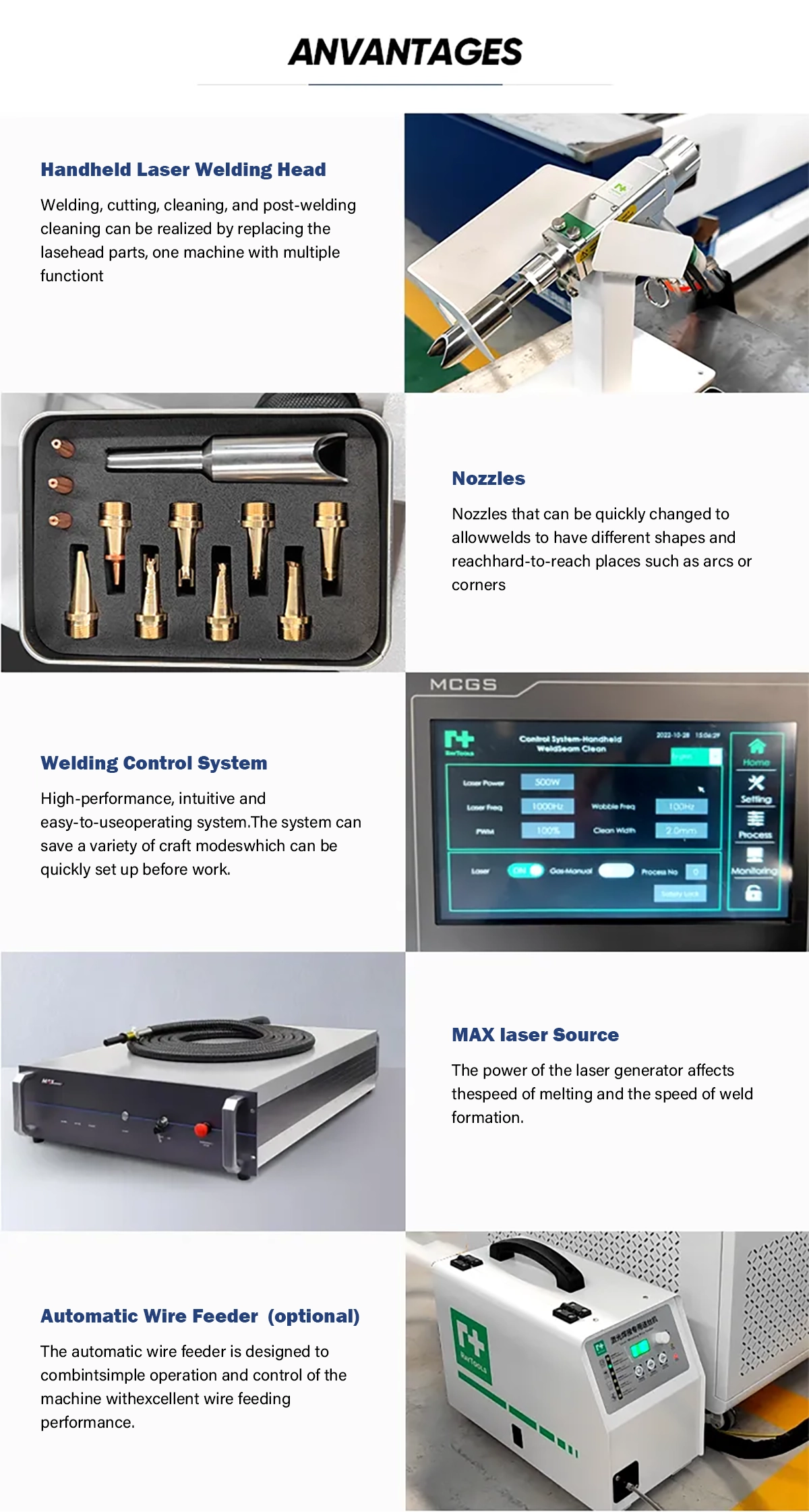

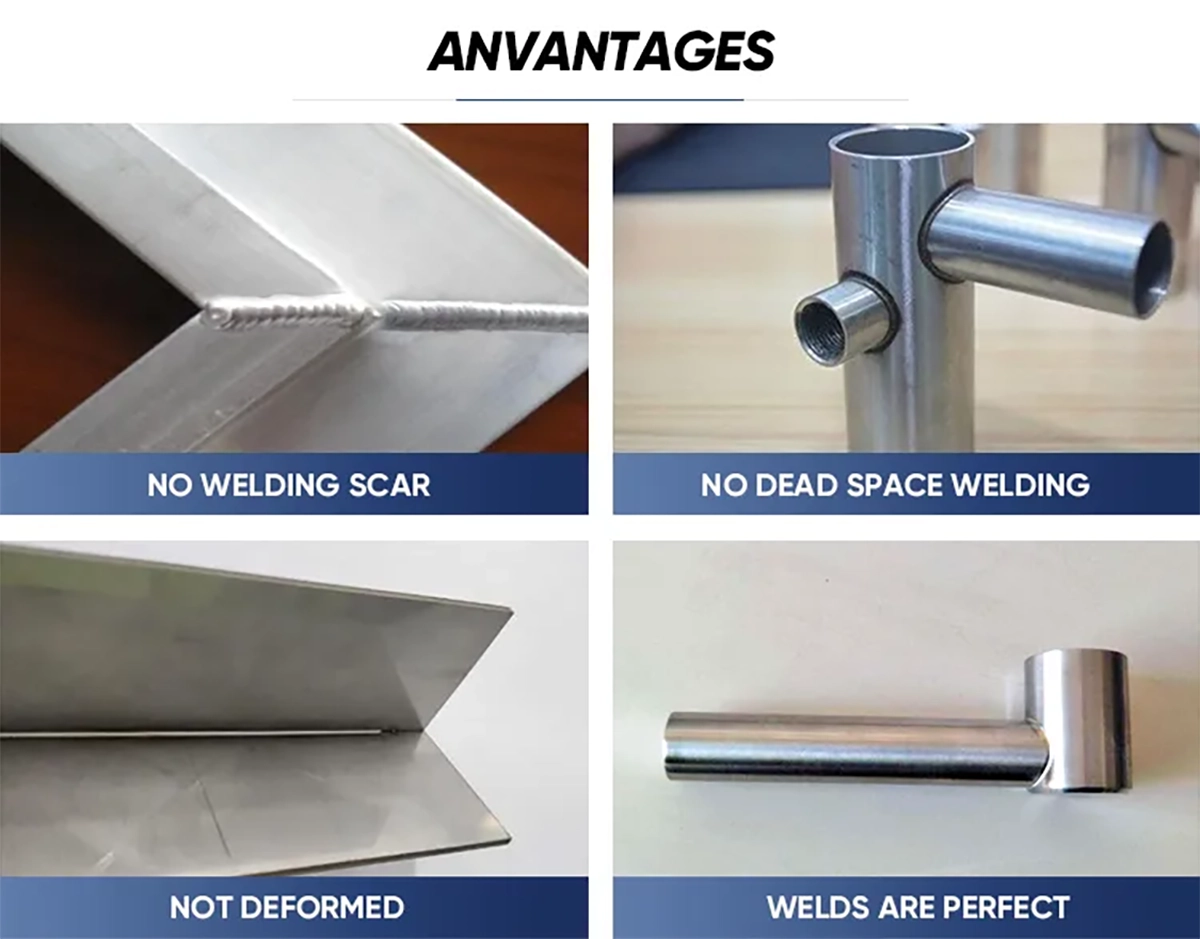

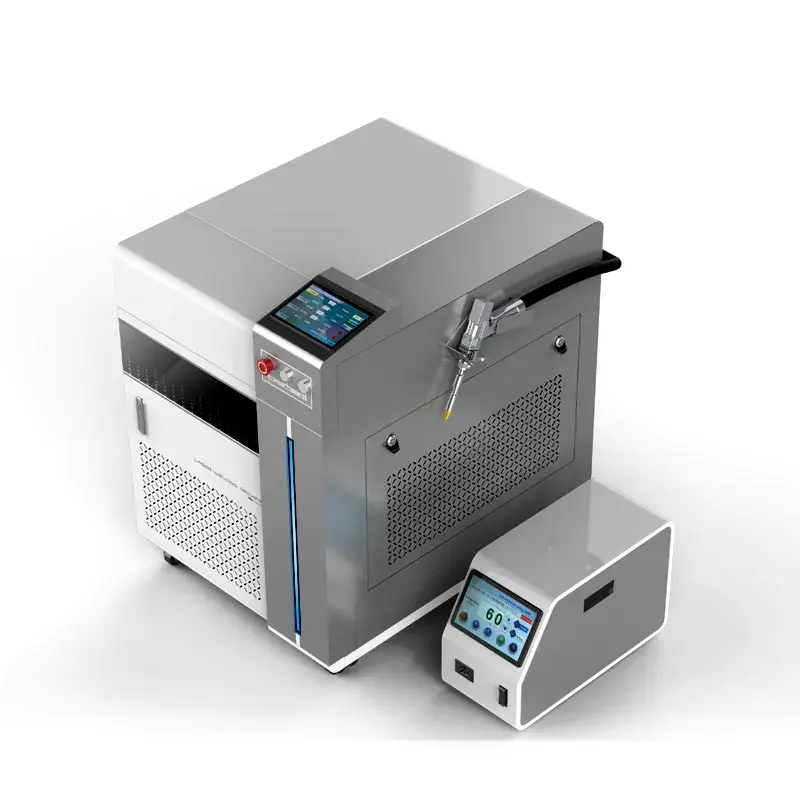

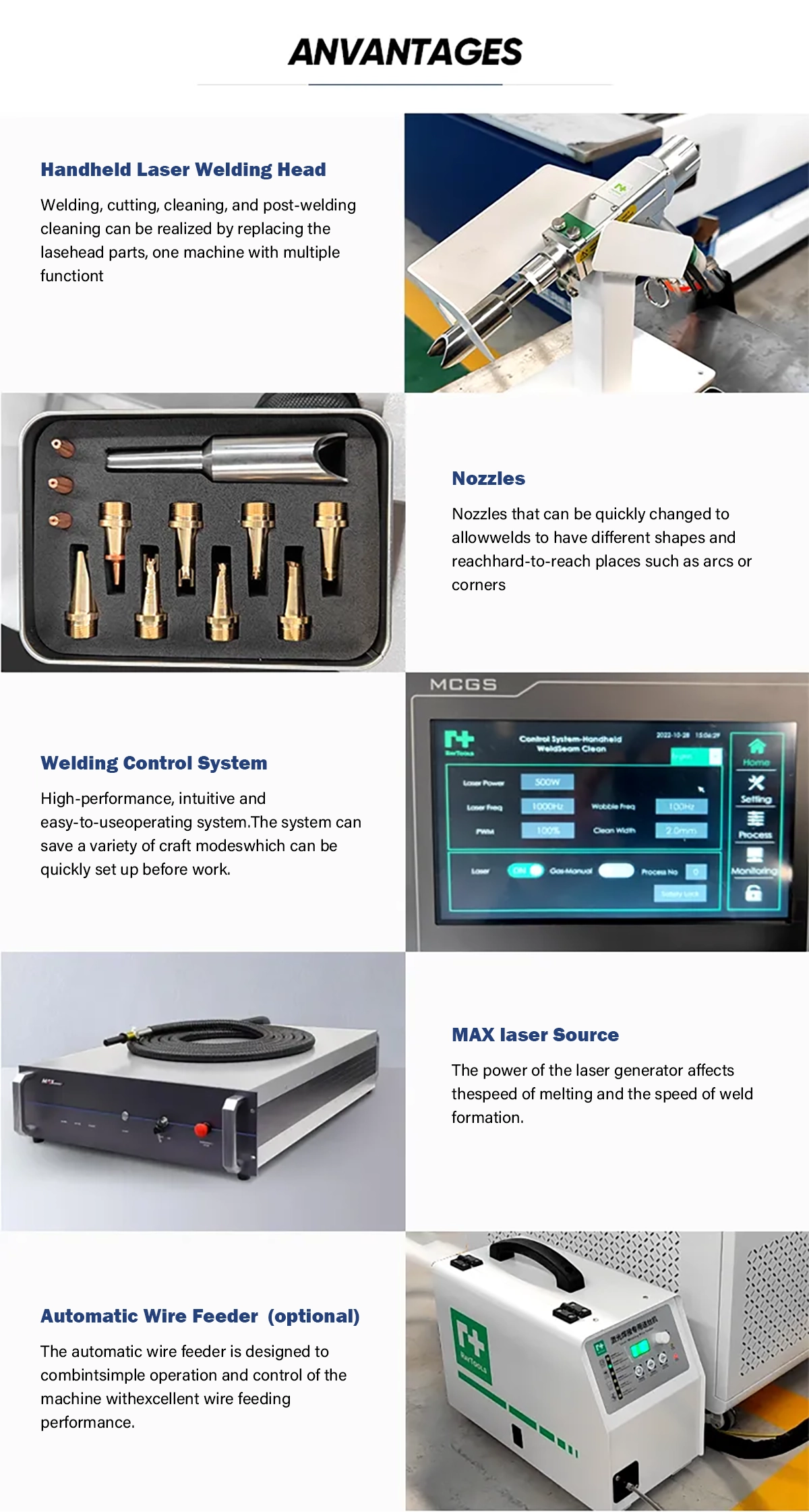

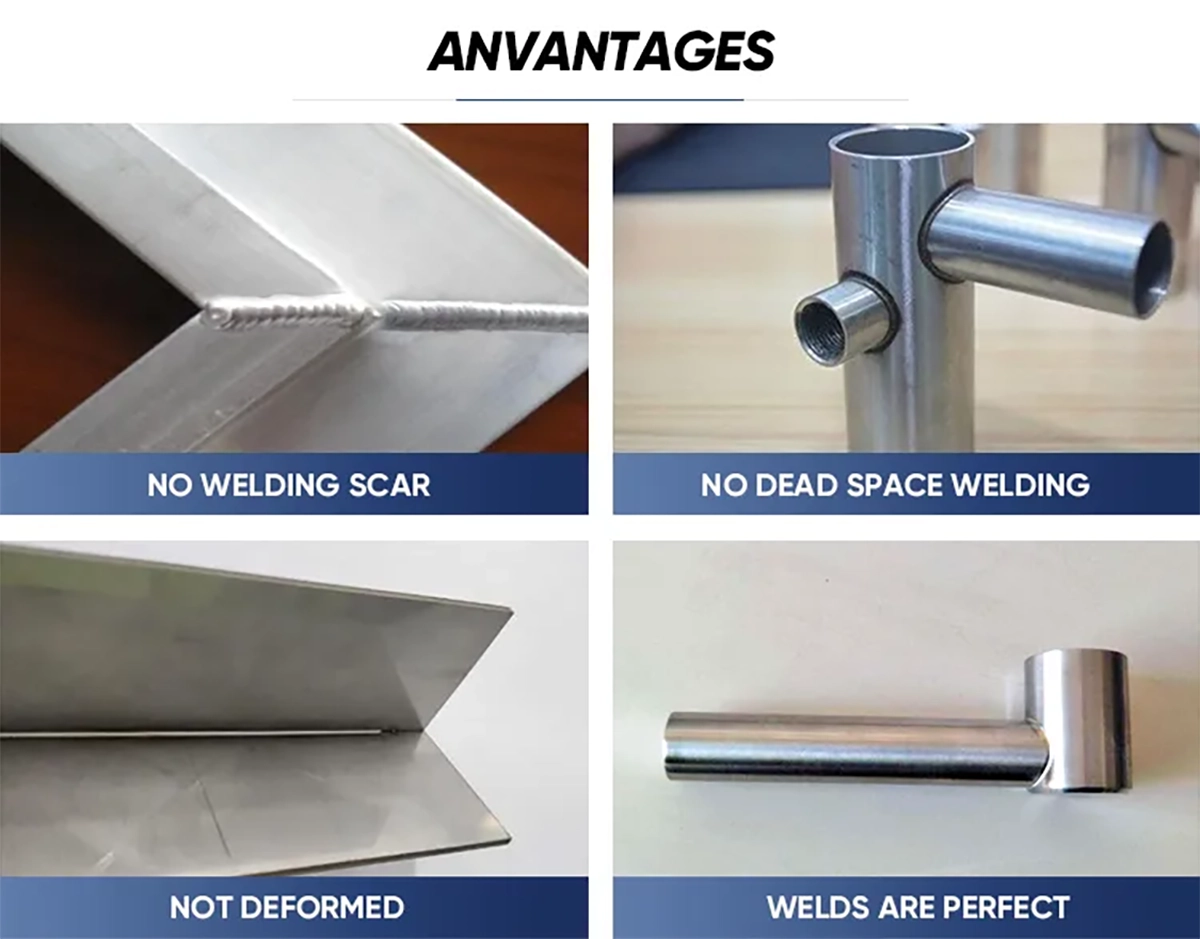

Compared with traditional welding techniques in production, laser welding is more environmentally friendly and easier to operate. Laser technology is more popular, bigger in your budget and is the most important and safer machine. With a variety of welding methods: spot welding, butt welding, lap welding, sealing welding, etc. can be realized. High aspect ratio, small weld width, small heat-affected zone, small deformation, fast welding speed, smooth and beautiful weld seam, no need or simple treatment after welding. High quality welding seam, no porosity, can be precisely controlled, small focal point, high positioning accuracy, easy to automate.

Stable operation, beautiful weld seam, fast welding speed, no consumables. It perfectly renews traditional welding strategies: arc welding and electric welding of the following materials: stainless steel, iron, galvanized or different metallic materials.

Different welding methods can be easily realized by changing different welding heads. The welding speed is faster, 2-10 times faster than traditional welding. Each machine saves labor costs of at least 2 operators per year, consumes less, has a longer life, and welding is safer and more environmentally friendly.

Easy operation: no experienced welding operators are required, novices can operate it.

Little or no post-processing: No polishing machine or sander is required, which greatly saves labor and time costs.

Laser welding is widely used in complex and abnormal welding processes: kitchen cabinets, stair lifts, shelves, ovens, stainless steel door and window guardrails, power distribution, various high-reflective metals and other industries

Common problems and solutions of laser cutting machine

The laser cutting head can’t be cut off completely, or inaccurate and out of positionadmin2023-06-08T03:21:28+00:00

- The power of the laser tube is weak and needs to be replaced;

- The film on the focus lens and reflecting lens is worn or contaminated, and it needs to be cleaned or replaced with anhydrous alcohol;

- If the light is offset and not correct, first adjust the light from the laser tube to the reflector lens, and then adjust the light reflected the focus lens to ensure that it is preset at the upper left, lower left, upper right, lower right and middle points of the platform, and the light is emitted from the laser nozzle hole;

- The worktable is not flat, and allowance shall be less than 2-3mm. The thicker the material is cut, the higher it requires. Adjust or replace it;

- The screw on the running synchronous wheel may be loose, or the belt may be loose. Tighten it with the hexagon socket;

- The reason why the sawtooth is cut out or the light is always adjusted incorrectly is that a lens is loose, tighten it before adjustment or use;

The machine does not move or the size of the cut figure changes irregularlyadmin2023-06-08T03:19:12+00:00

- Start up and check whether the driver and motor are powered on (if yes the driver cannot be pushed by hand). The green light is on when the driver works normally. If the track of the motor can be pushed after power is on, the motor shaft may be broken and the motor needs to be replaced;

- The power supply for the drive is generally DC 24V to DC 60V. Use a multimeter to check whether the switching power supply is normal. If not, it needs to be replaced;

The sound of jamming occurs when the laser cutting head movesadmin2023-06-08T03:18:34+00:00

- Check whether the bearing beads in the synchronous wheel are broken and need to be replaced;

- If the camera is used for automatic cutting, the camera data signal line may be broken in the middle during the identification process of the laser engraving, which needs to be replaced;

- Check whether the motor shaft is broken and needs to be replaced;

The cut figure size is inaccurateadmin2023-06-08T03:17:57+00:00Adjust the software file settings. The pulse equivalent in the workbench is generally 6400 pulses per movement of 32. According to different machines, 32 can be increased or decreased, and fine adjustments can be made to achieve good cutting accuracy;

Abnormal phenomena such as random walking or stopping of the machineadmin2023-06-08T03:17:30+00:00

- Generally, it is caused by the interference of static electricity on the control card. Recommend that the customer connect a reliable ground wire on the shell and the shell of the laser power supply;

- When the offline card is working, it is recommended to unplug the USB cable connected to the computer to avoid interference and shutdown;

The laser cutting head does not emit lightadmin2023-06-08T03:16:51+00:00

- Check whether the water circulates normally and let the water circulate normally. If the water protection is broken, please use short-circuit water protection;

- Click preset to see whether the ammeter swings. If not, use a multimeter to measure whether the laser power supply is 220V. If yes, the power supply may be faulty and needs to be replaced;

- GND ground wire and P water protection nipple on the power supply can also be used to test whether the water protection is broken. Short circuit + 5V and AIN to check the output high power. If the light comes, the potentiometer is broken and needs to be replaced:

- If there is no light in the program, the connected card can use a multi-meter to measure whether there is a DC voltage of more than 3V between corner 15 (H) or 16 (L) and corner 14. If yes, it indicates that the card is normal and otherwise there is a possible problem with the signal of the card;

- If there is a noise in the laser power supply, generally the power connector is in poor contact. Re weld or connect it, and then blow the dust in the power supply;

Can laser cutting machines cut any material?admin2023-04-22T02:05:37+00:00No, laser cutting machines are typically best suited for materials such as metal, plastic, wood, and fabric. Some materials like glass or certain types of reflective metals may be difficult to cut with a laser.

What materials can be processed with laser cutting machines?admin2023-04-22T02:07:45+00:00Laser cutting machines can process a wide variety of materials, including metals (such as steel, aluminum, and titanium), plastics, wood, and fabrics.

Can a laser cutting machine also do laser engraving?admin2023-04-22T02:09:57+00:00Yes, some laser cutting machines can also do laser engraving. It depends on the machine’s capabilities and the type of workpiece material. Laser engraving requires less power than laser cutting, so a laser cutting machine may need a lower power laser source or different optics to perform the task.

What materials can be processed with laser cutting machines?admin2023-04-22T02:10:06+00:00Laser cutting machines can process various materials, including metal, wood, acrylic, plastic, and more.